MagneBoss Belt Controller

Accessories

Pull Key

|

Spill Switch

|

Tilt Switch

|

Belt Alignment Switch

|

Water Spray Unit

|

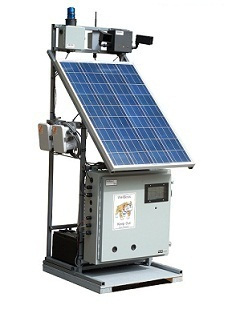

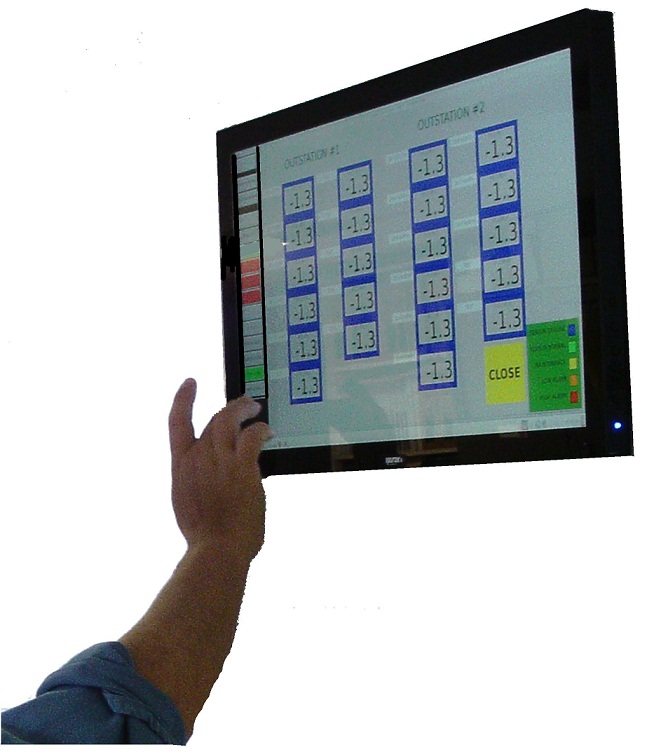

Put the floodlights on your belt performance, problems and productivity. MagneBoss monitors the speed and slip of every belt in your system. It magnetically monitors four belt-speed parameters at every drive -- belt idler and drive-roller speeds (to determine slip), the out-bye belt speed, the load-idler (for activating water spray.) Distributed intelligence includes a PLC at each belt drive, providing fast fault detection and responses. In addition, the MagneBoss system includes a network computer on the surface which supervises the status of all belts; graphically displaying belt speeds, faults and down-time data for maximizing production.

Multiple conditions -- The MagneBoss can also monitor a host of safety and production sensors at each belt: such as blocked-chute, spillage, misalignment, torn-belt, vibration, over-current, hydraulic pressures, temperatures, smoke, carbon-monoxide, methane, air-velocity and such. Even belt scales can be added at strategic points, with tonnage figures added to the on-screen belt-status profile. All this information is stored on the central computer hard drive, which presents a hugely valuable resource for data mining; discovering where improvements are necessary to keep production humming.

ORDER NOW

(Hover over the images to enlarge)

Features:

- Networkable throughout the mine or plant, wired or wireless.

- Monitors for slip and sequencing. Accommodates a host of instruments for detecting blocked chute, spillage and misalignment. Controls dust suppression sprayers. Add fire detection and fire suppression. An emergency stop switch and pull-key monitoring are standard.

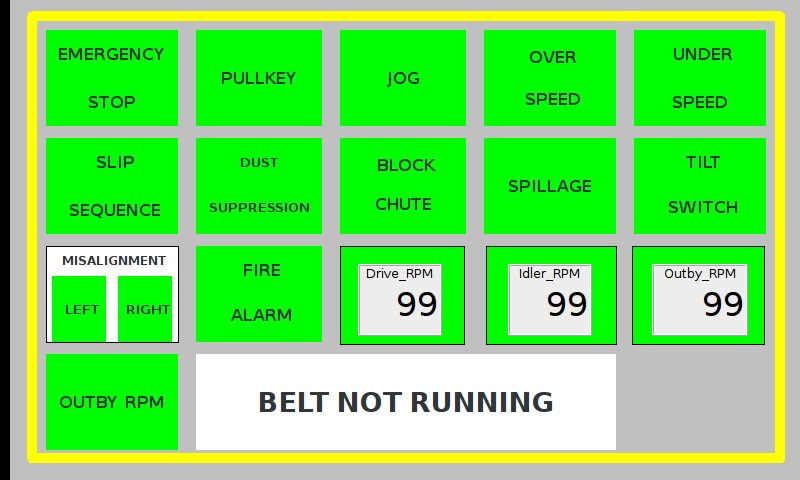

- Displays belt status locally on a 7” color, touchscreen. A library of popup alarm messages show fault conditions by name.

- Two digital RPM sensors input belt and drive speeds locally. A third RPM sensor monitors the outby belt speed for proper sequencing control.

- 5.) Automatic calibration of RPM sensors is available by running the belt empty and pressing RPM

sensor buttons to capture the max speeds. Then set the desired slip speed ratio – eg 50% or 80% FS -- to suit.

The local computer memory archives alarm data by date and time. Exchange the pen-drive memory stick to remove files for off line viewing and printing.

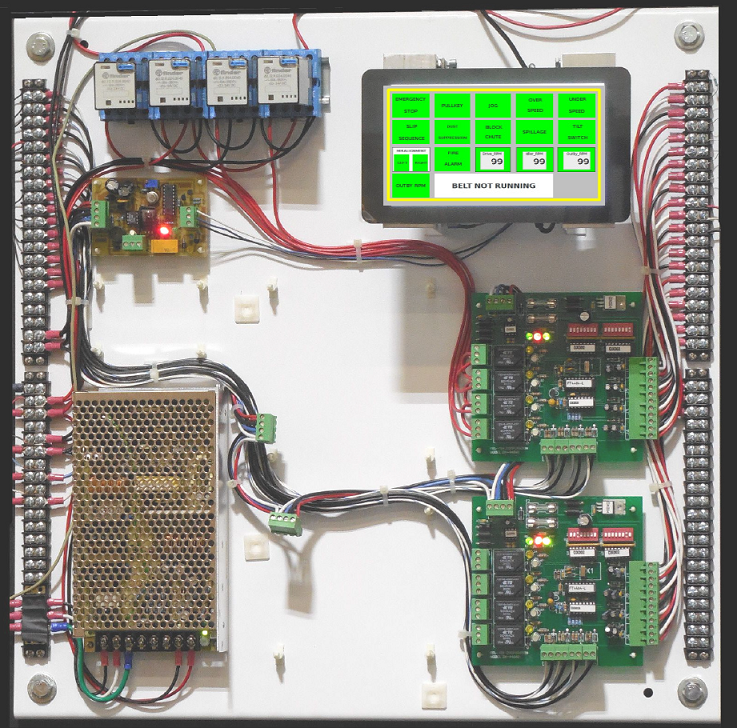

Computer and I/O circuitry are housed in a 24”x24”x8” steel, NEMA-12, dust tight enclosure. The touch screen display is housed inside the panel, viewable from the outside through a plastic window.

- Power for the system is 110VAC to the main panel, drawing, typically 1-2 amps.

- Networking to the surface is available through a wireless tracking system supplied by Innovative Wireless Technology (IWT) with offices in Lynchburg, VA.

- Alternatively, networking is also available via twisted pair wires or optical fiber cables by Rel-Tek Corporation.

- MagneBoss internals shown with standard configuration. Additional I/O cards available as needed.

- Pull-key emergency stop boxes can be monitored collectively (i.e. one alarm for a string of boxes

- Optional fire suppression is available by adding thermal fire sensors and deluge nozzles, directing water onto the belt from a water main source.

- Systems are flexible, allowing use of existing belt sensing devices that may be available on a retrofit situation. Or, these devices can be supplied by Rel-Tek or IWT to suit client’s needs.

Accessories

|

Pull Key

Pull Key - On/OFF Pull Cord Switch (Pull Key) provides quick response shut-off of equipment. For more information, Click Here |

|

Spill Switch - Spillage Switch is designed to trip and shutdown the conveyor system when a predetermined amount of spillage is present to activate the switch (pressure plate). For more information, Click Here |

|

Tilt Switch - Paddle Switch (Tilt) is designed to trip when the extension’s travel exceeds the pre-set points. For more information, Click Here |

|

Belt Alignment Switch is designed to trip when the control arm’s travel exceeds the pre-set points. Upon proper installation, the alignment switch roller is positioned so that if the conveyor belt does not track properly the belt will make contact with the roller forcing it to trip the contacts. For more information, Click Here |

|

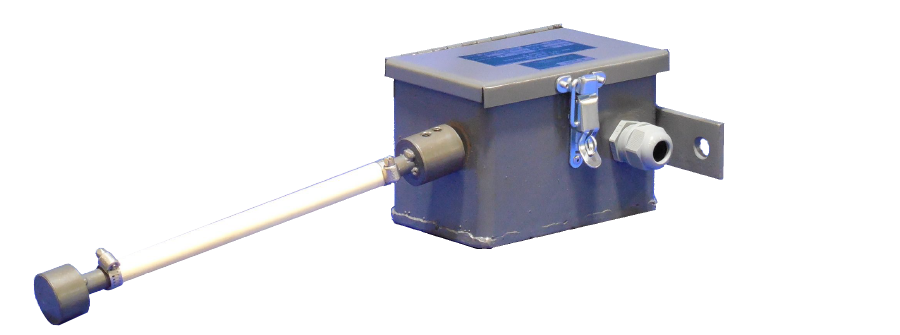

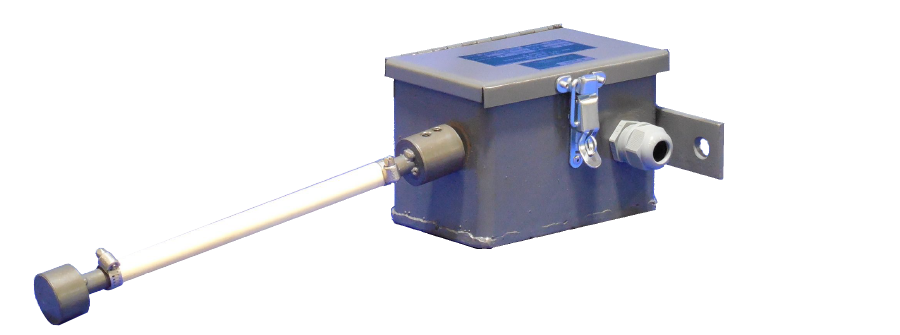

Water Spray Unit is designed to activate when the roller makes contact with the belt and exceeds the pre-set points. For more information, Click Here |

|