Introducing: SpillBoss - Spillage Sensor for conveyor belt

|

ORDER NOW Spill Switch is designed to trip and shutdown the conveyor system when a predetermined amount of spillage is present to activate the switch (pressure plate). This helps to eliminate Spillage or Spill Switch buried head and tail pieces of the conveyor belt. Typical applications would include all bins, hoppers, belt heads, and tail pieces and anywhere spillage is a problem. Face hinged pressure plate toward belt (coal). Wire to the normally open contacts of switch and the pre-determined digital input of the controller (if applicable). Wiring- White wire is COMMON. Black Wire is NC (Normally Closed with magnet engaged) Red Wire is NO (Normally Open with magnet engaged) Click Here For More (click on the image to enlarge) |

||

Delivering the Best Solutions and Services to our customers.

Rel-Tek engineers design and plan a complete monitoring and control system to meet all your specific requirements, while keeping you Ahead, Way Ahead

MSHA, CANMET, UL, etc Approved Sensors, Equipment and accessories

There are over 100 approvals (MSHA, CANMET, NYC-MEA, and UL standards) covering Rel-Tek environmental sensors and accessories for use in various applications.

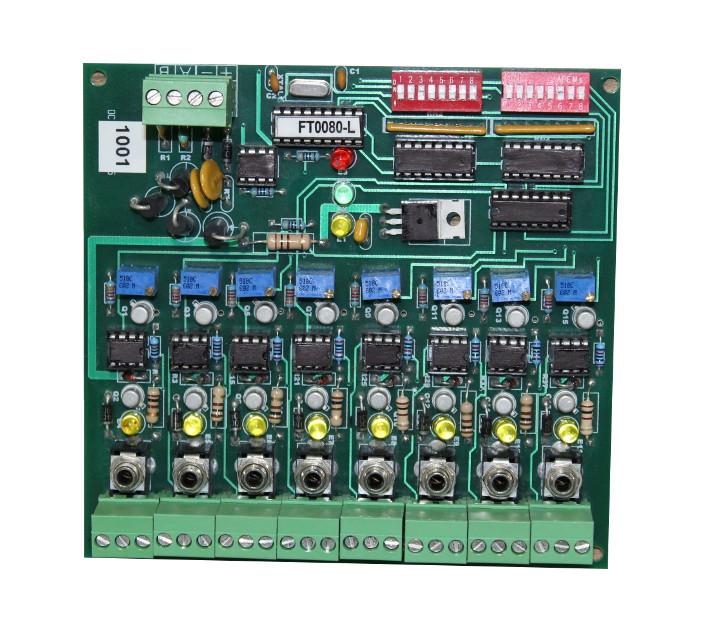

Read MoreDependable Hardware

Rel-Tek's hardware are the best in the industry. They are very low maintenance and are designed and manufactured in house from ground up.

Read MoreA+++ Services

At Rel-Tek, we truly care about our customers and go out of our way to help them. That also includes troubleshooting our systems over the phone and the Internet in the event customers need help. Plus, we offer on-site quarterly maintenance service.

Read MoreState of the Art Technology (Software/System)

We have state of the art technology for gas monitoring systems, which was built from the ground up by Rel-Tek Corporation.

Read MoreNews/Events

We attend events and shows to meet with people in other industries and potential customers showcasing our products and technologies

Read MoreNow Available. Touchscreen Wall-Mount System with virtual keyboard

Touchscreen Wall-Mount Computer was designed for use as a zone monitoring device. This device can monitor its own zone or remotely look at other zones through the primary computer.

Read MoreRel-Tek Corporation is ahead... way ahead.

We have state of the art technologies and equipment for all of your needs for your site(s).

What People say’s About us

Partners